Precision CNC Machining Gears: Everything You Need to Know

By:Admin

One of Hyluo Inc.'s standout products is their CNC machined gears. These gears are crucial components in a wide range of industries, including automotive, aerospace, robotics, and electronics. Known for their precision and durability, Hyluo Inc.'s CNC machined gears are sought after by companies looking to optimize the performance of their machinery and equipment.

CNC machining, or computer numerical control machining, is a manufacturing process that uses computerized controls and machine tools to remove material from a workpiece, creating custom precision parts and components. Hyluo Inc. has honed their expertise in this advanced manufacturing technique, allowing them to produce gears with incredibly tight tolerances and complex geometries.

The use of CNC machining in gear production offers numerous advantages. The process allows for high levels of precision and repeatability, ensuring that each gear meets the exact specifications required for its intended application. Additionally, CNC machining is capable of producing gears with intricate designs and features that would be difficult or impossible to achieve using traditional manufacturing methods.

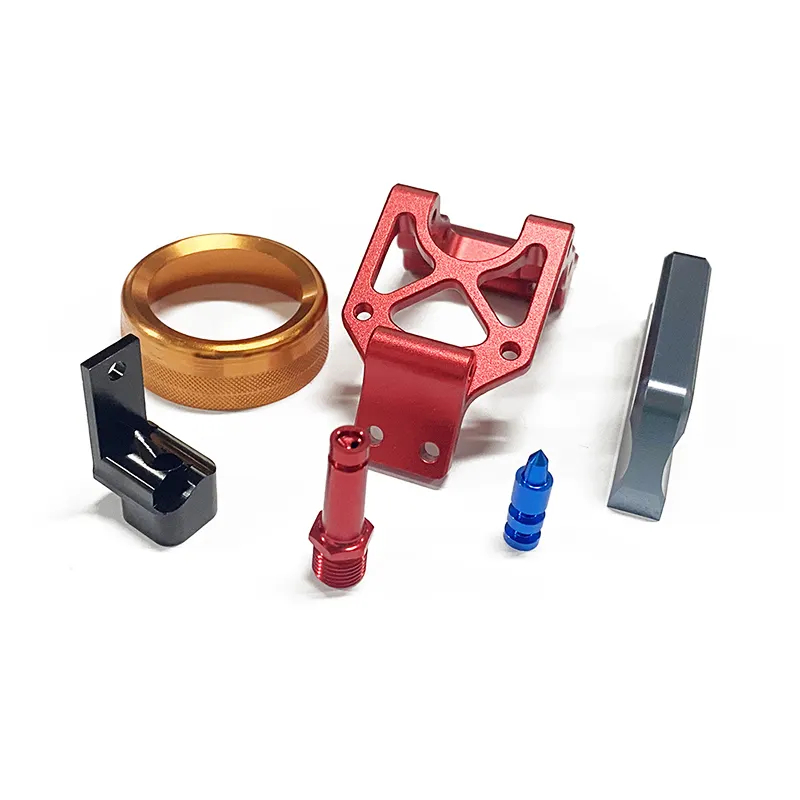

Hyluo Inc.'s CNC machined gears are made from a variety of materials, including aluminum, stainless steel, copper, titanium, and plastic. This diverse range of materials allows the company to cater to the unique needs of different industries and applications. Whether a gear needs to withstand high temperatures, corrosive environments, or extreme mechanical stresses, Hyluo Inc. has the expertise to select the right material and machining process to deliver a solution that meets the highest standards of quality and performance.

The aerospace industry, in particular, benefits from Hyluo Inc.'s CNC machined gears. Aerospace applications demand gears that can operate in the harshest of environments, from the extreme temperatures of space to the high speeds and forces encountered in aircraft propulsion systems. Hyluo Inc.'s gears are designed and manufactured to meet these rigorous performance requirements, providing aerospace companies with components they can rely on for the most demanding missions and operations.

In the automotive industry, where efficiency, reliability, and performance are paramount, Hyluo Inc.'s CNC machined gears play a crucial role in ensuring the smooth and efficient operation of vehicle transmissions, engines, and other drivetrain systems. The company's commitment to delivering top-quality gears has earned them a reputation as a trusted partner for automotive manufacturers looking to enhance the performance and durability of their vehicles.

Hyluo Inc.'s CNC machined gears have also found applications in the field of robotics, where precision and reliability are essential for the smooth functioning of robotic systems. By delivering gears that meet the highest standards of accuracy and performance, Hyluo Inc. has become a preferred supplier for robotics companies seeking to enhance the capabilities of their automation and robotics solutions.

With a track record of delivering high-quality CNC machined gears and components to companies worldwide, Hyluo Inc. is well-positioned to continue making a significant impact in the manufacturing industry. Through their expertise in CNC machining and their commitment to meeting the unique needs of their customers, the company is poised to remain a key player in the supply chains of industry-leading manufacturers for years to come.

Company News & Blog

High-Quality Precision CNC Turning Services: A Complete Guide

Precision CNC Turning: The Future of ManufacturingIn the world of manufacturing, precision is everything. Companies are constantly searching for the most reliable and efficient methods of producing high-quality products with minimal margin for error. This is where precision CNC turning comes in. With the advanced technology and expertise in this field, Precision CNC Turning (PCT) is revolutionizing the manufacturing industry and setting the standard for precision engineering.At the heart of Precision CNC Turning (PCT) is its state-of-the-art facility, which boasts a wide range of CNC turning machines. These machines are capable of producing complex and intricate components with unparalleled precision. With the ability to work with a variety of materials, including aluminum, steel, titanium, and more, PCT has the capability to accommodate the diverse needs of its clients across various industries.Founded in 1999, PCT has steadily positioned itself as a leader in the CNC turning industry. The company has earned a reputation for delivering high-quality products, unparalleled precision, and exceptional customer service. With a team of experienced engineers and technicians, PCT has the expertise and knowledge to tackle even the most challenging projects.One of the key strengths of PCT is its ability to offer custom solutions to its clients. Whether a company requires a prototype or a large-scale production run, PCT can accommodate their needs. This flexibility has allowed PCT to establish strong relationships with a wide range of clients, from small businesses to Fortune 500 companies.In addition to its cutting-edge technology and skilled workforce, PCT is committed to staying ahead of the curve when it comes to industry advancements. The company continuously invests in research and development to ensure that it remains at the forefront of CNC turning technology. By doing so, PCT is able to adapt to the ever-evolving needs of the manufacturing industry and provide its clients with the most innovative solutions.One way in which PCT has set itself apart is through its dedication to quality control. Every component that comes out of its facility undergoes rigorous inspections to ensure that it meets the highest standards. This commitment to quality has earned PCT numerous certifications and accreditations, further solidifying its reputation as a trusted partner in the manufacturing sector.Furthermore, PCT is also devoted to sustainability and environmental responsibility. The company strives to minimize its impact on the environment by implementing eco-friendly practices throughout its operations. From reducing waste to optimizing energy efficiency, PCT is dedicated to being a responsible corporate citizen.Looking ahead, PCT is well-positioned for continued success and growth. With an unwavering commitment to precision and innovation, the company is poised to further establish itself as a leader in the CNC turning industry. As the demand for high-quality, precision-engineered components continues to rise, PCT is ready to meet the needs of its clients and exceed their expectations.In conclusion, Precision CNC Turning is shaping the future of manufacturing. With its cutting-edge technology, experienced workforce, commitment to quality, and dedication to innovation, PCT is setting the standard for precision engineering. As the industry continues to evolve, PCT remains steadfast in its mission to deliver exceptional products and customer service. Whether a company requires a small prototype or a large-scale production run, PCT is the go-to solution for all precision CNC turning needs.

Discover the Latest Carbon Fiber CNC Technology News

Hyluo Inc., a company specializing in custom precision CNC machined components, has announced a new partnership with a leading carbon manufacturing company to further expand its product offerings. The partnership will allow Hyluo Inc. to provide CNC carbon parts to its customers, further solidifying its position as a key player in the supply chains of industry leading manufacturers.Hyluo Inc. has been manufacturing precision machined components for companies worldwide for over 10 years. With a focus on CNC aluminum parts, CNC processing stainless steel parts, CNC copper parts, CNC titanium parts, CNC plastic parts, and now CNC carbon parts, the company has established itself as a reliable and innovative supplier in the industry.The addition of CNC carbon parts to Hyluo Inc.'s product lineup comes at a time when the demand for lightweight and durable components is on the rise across various industries. Carbon fiber is known for its high strength-to-weight ratio, making it an ideal material for a wide range of applications, including automotive, aerospace, marine, and sporting goods."We are thrilled to be partnering with [Carbon Manufacturing Company] to bring CNC carbon parts to our customers," said the CEO of Hyluo Inc. "This collaboration aligns with our commitment to providing high-quality, custom machined components that meet the evolving needs of our clients. With the addition of CNC carbon parts, we are well-positioned to support the growing demand for lightweight and high-performance components across various industries."The CNC carbon parts offered by Hyluo Inc. will be manufactured using advanced machining techniques and state-of-the-art equipment to ensure precision and consistency in every component. Customers can expect a wide range of carbon parts, including but not limited to brackets, fittings, housings, and custom-designed components tailored to their specific requirements.In addition to the manufacturing capabilities, Hyluo Inc. will also provide engineering and design support to assist customers in optimizing the performance and manufacturability of their carbon parts. This comprehensive approach underscores the company's commitment to delivering value-added solutions to its clientele.The integration of CNC carbon parts into Hyluo Inc.'s product portfolio is expected to open up new opportunities for the company, as well as its customers. The lightweight and high-strength properties of carbon fiber make it an attractive material for various applications, such as reducing the overall weight of automotive components, enhancing the performance of aerospace structures, and improving the efficiency of marine and sporting goods equipment.As the industry continues to evolve, Hyluo Inc. remains dedicated to staying at the forefront of technological advancements and material innovations. The company's investment in CNC carbon parts reflects its strategic vision to offer comprehensive solutions that address the dynamic needs of modern manufacturing.With the partnership in place and the expansion of its product offerings, Hyluo Inc. is well-poised to continue its trajectory of growth and success in the CNC machining industry. The company's commitment to quality, innovation, and customer satisfaction positions it as a trusted partner for companies seeking reliable and customized precision machined components.Overall, Hyluo Inc.'s partnership with a leading carbon manufacturing company marks an important milestone in the company's journey to diversify its product range and strengthen its position as a key player in the global supply chain. The addition of CNC carbon parts underscores the company's dedication to meeting the evolving needs of its customers and demonstrates its readiness to embrace new opportunities in the ever-changing landscape of manufacturing.

Local CNC Machining Services for Your Needs

Hyluo Inc. has been a leading provider of custom precision CNC machining services for over a decade, offering high-quality components for companies worldwide. Specializing in CNC aluminum parts, CNC stainless steel parts, CNC copper parts, CNC titanium parts, and CNC plastic parts, the company has established itself as an integral part of the supply chains of many industry-leading manufacturers.In order to better serve its customers, Hyluo Inc. has announced the expansion of its CNC machining services with the opening of a new facility, aiming for greater convenience for clients and increased capacity for production.The new facility, conveniently located in the heart of [location], is equipped with state-of-the-art CNC machining technology and staffed by a team of highly skilled and experienced technicians. This expansion allows Hyluo Inc. to offer even more comprehensive CNC machining solutions, ensuring the highest level of precision and quality for each component produced."We are thrilled to announce the opening of our new facility, which represents a significant milestone for Hyluo Inc.," said [spokesperson], CEO of the company. "Our continued commitment to investment in cutting-edge technology and operational expansion is a testament to our dedication to meeting the evolving needs of our customers."With the new facility, Hyluo Inc. is now able to provide an even wider range of CNC machining services, including milling, turning, drilling, tapping, and more. This enables the company to accommodate a diverse array of projects, from small-scale prototypes to large-scale production runs, while maintaining the same high standard of quality and precision.In addition to its expanded capacity, the new facility also brings Hyluo Inc. closer to its customers, offering more convenience for those in the [location] area seeking CNC machining services. The company's strategic decision to locate the new facility in an accessible location underscores its commitment to providing efficient and reliable solutions for clients' machining needs.As part of its continued growth and commitment to excellence, Hyluo Inc. has also invested in additional staff training and development to ensure that its team remains at the forefront of the industry. The company's highly skilled technicians undergo regular training to stay abreast of the latest advancements in CNC machining technology and techniques, enabling them to consistently deliver superior results.Furthermore, Hyluo Inc. remains dedicated to environmental sustainability and has integrated eco-friendly practices into its operations. The company adheres to stringent environmental standards and strives to minimize its carbon footprint through responsible resource management and the use of sustainable manufacturing processes."We are proud to uphold the highest standards of environmental responsibility in our operations, and the new facility has been designed with sustainability in mind," [spokesperson] added. "By prioritizing eco-friendly practices, we are not only reducing our environmental impact but also providing our customers with the assurance that their components are being produced with ethical and sustainable principles."The expansion of Hyluo Inc.'s CNC machining services represents a significant advancement for the company, further solidifying its position as a trusted partner for precision manufacturing. With its new facility and enhanced capabilities, Hyluo Inc. is poised to meet the evolving needs of its customers with unparalleled quality, precision, and efficiency.As the company continues to grow and innovate, it remains steadfast in its commitment to delivering exceptional CNC machining solutions, maintaining its reputation as a leader in the industry. With its expanded capacity, skilled team, and unwavering dedication to excellence, Hyluo Inc. is well-positioned to meet the evolving demands of companies worldwide for high-quality, custom precision machined components.For more information about Hyluo Inc.'s expanded CNC machining services and the new facility, interested parties are encouraged to visit the company's website or contact their representatives directly to discuss their specific machining needs and requirements.

Leading Precision Turning Company Provides Top-Quality Services for Manufacturing Needs

Precision Turning Inc, a leading manufacturer of custom precision CNC machined components has announced a strategic partnership with Hyluo Inc. The collaboration between the two companies is poised to revolutionize the industry and offer unparalleled precision and quality to their customers.Hyluo Inc. has been in the business of manufacturing precision machined components since 2010. With over a decade of experience, the company has established itself as a trusted partner for companies worldwide. They have been an integral part of the supply chains of many industry-leading manufacturers, providing a wide range of CNC machined components including aluminum parts, stainless steel parts, copper parts, titanium parts, plastic parts, and more.Precision Turning Inc, on the other hand, is known for its expertise in producing high-quality custom precision CNC machined components. With a focus on precision and accuracy, the company has built a reputation for delivering superior products to its customers. By joining forces with Hyluo Inc, Precision Turning Inc aims to further enhance its capabilities and expand its product offerings.The partnership between the two companies is expected to bring together their expertise and resources to provide customers with a comprehensive range of precision machined components. By leveraging their combined strengths, they aim to offer innovative solutions and unmatched quality to their customers across various industries.One of the key benefits of this collaboration is the ability to offer a wider range of materials and capabilities. Hyluo Inc's extensive experience in working with different materials such as aluminum, stainless steel, copper, titanium, and plastic, combined with Precision Turning Inc's precision machining capabilities, will enable them to cater to diverse customer requirements.Additionally, the partnership will also enable both companies to streamline their operations and optimize their manufacturing processes. By leveraging each other's expertise and resources, they aim to enhance efficiency and reduce lead times, ensuring faster delivery of high-quality precision machined components to their customers.Furthermore, the collaboration between Precision Turning Inc and Hyluo Inc is expected to open up new opportunities for both companies in terms of market expansion and customer acquisition. By combining their strengths, they aim to reach new customers and expand their presence in the global market, solidifying their position as industry leaders.The partnership is also expected to drive innovation and continuous improvement in the production of precision machined components. By sharing knowledge, best practices, and technology, the companies aim to stay ahead of the curve and meet the evolving needs of their customers in an increasingly competitive market."We are thrilled to announce our partnership with Hyluo Inc," said a spokesperson for Precision Turning Inc. "By joining forces, we aim to offer our customers a wider range of precision machined components and unparalleled quality. We are confident that this collaboration will bring significant benefits to both companies and further strengthen our position in the industry."Overall, the partnership between Precision Turning Inc and Hyluo Inc marks an important milestone in the industry. By combining their expertise, resources, and capabilities, the two companies aim to raise the bar for precision machined components and provide customers with exceptional products and services. As they move forward with this partnership, they are poised to set new standards and drive innovation in the industry, ultimately benefiting their customers and the market as a whole.

High-Quality Metal Milling Services for Custom Projects

Hyluo Inc., a leading manufacturer of custom precision CNC machined components, is making waves in the metal milling industry with their latest technology and expertise. With a focus on quality and precision, Hyluo Inc. has been serving companies worldwide for over 10 years and has become an integral part of the supply chain for many industry-leading manufacturers.The company specializes in the production of CNC aluminum parts, CNC processing stainless steel parts, CNC copper parts, CNC titanium parts, CNC plastic parts, and more. Their dedication to excellence and their commitment to meeting the needs of their customers has set them apart from their competitors.Custom Metal Milling, a subsidiary of Hyluo Inc., is a key player in the metal milling industry. The company offers a wide range of milling services, including precision CNC milling, CNC turning, and metal fabrication. Their state-of-the-art equipment and skilled technicians allow them to produce high-quality, custom metal parts to exact specifications.One of the key factors that sets Custom Metal Milling apart from its competitors is its ability to work with a wide range of materials. Whether it’s aluminum, stainless steel, copper, titanium, or plastic, the company has the expertise and technology to produce precision parts from any material. This versatility allows them to cater to a diverse range of industries, from aerospace and automotive to medical and electronics.In addition to their broad range of capabilities, Custom Metal Milling is known for their strict adherence to quality standards. Their team of experienced machinists and engineers work tirelessly to ensure that every part meets the highest standards of quality and precision. This commitment to excellence has earned them a strong reputation in the industry and has helped them build long-lasting relationships with their customers.Custom Metal Milling is also committed to staying ahead of the curve when it comes to technology and innovation. They continuously invest in the latest CNC milling machines and software, as well as training programs for their staff, to ensure that they remain at the forefront of the industry. This dedication to staying ahead of the curve has allowed them to take on increasingly complex projects and deliver exceptional results to their clients.The company’s dedication to quality, precision, and innovation has not gone unnoticed. They have received numerous accolades and awards for their exceptional work, and have been recognized as a leader in the metal milling industry. These accolades serve as a testament to their unwavering commitment to excellence and their ability to consistently deliver superior products and services.Looking ahead, Custom Metal Milling is poised for continued growth and success. With their strong reputation, broad range of capabilities, and dedication to innovation, they are well-positioned to take on new challenges and expand their reach in the industry. The company has plans to further invest in their technology and infrastructure, as well as expand their team of skilled professionals, to ensure that they continue to meet the evolving needs of their customers.In conclusion, Custom Metal Milling, a subsidiary of Hyluo Inc., is making a significant impact in the metal milling industry. With their focus on quality, precision, and innovation, they have become a trusted partner for companies worldwide, delivering exceptional products and services. Their commitment to excellence and their dedication to staying ahead of the curve will undoubtedly propel them to even greater success in the years to come.

High-Quality Aluminium CNC Parts for Precision Machining Needs

Aluminium CNC Parts: A Versatile Solution for Precision MachiningIn today's fast-paced and constantly evolving manufacturing industry, the demand for high-quality, precision-machined parts continues to grow. As a leader in the field, {} has been at the forefront of providing innovative solutions to meet this demand. With their cutting-edge technology and expertise, they have brought to the market a versatile and efficient solution - Aluminium CNC Parts.The use of aluminium in CNC machining offers a wide range of benefits, making it a popular choice for various industries. Its lightweight yet durable properties make it ideal for applications where strength and weight are critical factors. Additionally, aluminium is known for its excellent corrosion resistance, which further extends the lifespan of the parts produced. With the ability to be easily shaped and formed, aluminium CNC parts can be tailored to fit specific design requirements, offering unparalleled versatility.With a wealth of experience in CNC machining, {} has perfected the art of creating precision aluminium parts. Their state-of-the-art facilities and advanced CNC technology allow for the production of complex geometries and intricate designs with exceptional accuracy and repeatability. This level of precision is crucial for industries such as aerospace, automotive, and electronics, where strict tolerances and exact specifications are non-negotiable.Moreover, {} understands the importance of delivering high-quality aluminium CNC parts in a timely manner. Their streamlined manufacturing processes and efficient workflow ensure rapid turnaround times without compromising on quality. This level of reliability and consistency has earned {} a stellar reputation as a trusted partner for businesses looking for top-notch CNC machined parts.In addition to their technical expertise, {} is committed to sustainability and environmental responsibility. Aluminium is a highly recyclable material, and {} has implemented eco-friendly practices into their manufacturing processes, minimizing waste and reducing their carbon footprint. This dedication to sustainability aligns with the growing global emphasis on environmentally conscious manufacturing practices.The applications of aluminium CNC parts are diverse and far-reaching. From intricate components for medical devices to specialized parts for the aerospace industry, the versatility and precision of aluminium CNC machining make it a valuable solution for a wide range of industries. Moreover, with the increasing demand for lightweight and durable materials, the need for aluminium CNC parts is expected to continue to rise.As the industry leader in CNC machining, {} is well-equipped to meet this growing demand. Their unwavering commitment to innovation, quality, and customer satisfaction sets them apart in the market. By continually investing in new technologies and staying at the forefront of industry trends, {} remains at the cutting edge of CNC machining, providing their clients with superior aluminium parts that exceed expectations.In conclusion, aluminium CNC parts offer a versatile and efficient solution for precision machining needs. With {}'s expertise and advanced capabilities, they are well-positioned to meet the growing demand for high-quality aluminium CNC parts across various industries. Their commitment to excellence, sustainability, and customer satisfaction solidifies {} as a leader in the CNC machining industry. As the market evolves, {} will undoubtedly continue to drive innovation and set new standards for precision manufacturing.

Precision CNC Machining Gears: Everything You Need to Know

Hyluo Inc. has been making waves in the manufacturing industry since 2010. Specializing in custom precision CNC machined components, the company has become an integral part of the supply chains of many industry-leading manufacturers around the world. With a decade of experience under their belt, Hyluo Inc. continues to provide high-quality CNC aluminum parts, CNC processing stainless steel parts, CNC copper parts, CNC titanium parts, CNC plastic parts, and more.One of Hyluo Inc.'s standout products is their CNC machined gears. These gears are crucial components in a wide range of industries, including automotive, aerospace, robotics, and electronics. Known for their precision and durability, Hyluo Inc.'s CNC machined gears are sought after by companies looking to optimize the performance of their machinery and equipment.CNC machining, or computer numerical control machining, is a manufacturing process that uses computerized controls and machine tools to remove material from a workpiece, creating custom precision parts and components. Hyluo Inc. has honed their expertise in this advanced manufacturing technique, allowing them to produce gears with incredibly tight tolerances and complex geometries.The use of CNC machining in gear production offers numerous advantages. The process allows for high levels of precision and repeatability, ensuring that each gear meets the exact specifications required for its intended application. Additionally, CNC machining is capable of producing gears with intricate designs and features that would be difficult or impossible to achieve using traditional manufacturing methods.Hyluo Inc.'s CNC machined gears are made from a variety of materials, including aluminum, stainless steel, copper, titanium, and plastic. This diverse range of materials allows the company to cater to the unique needs of different industries and applications. Whether a gear needs to withstand high temperatures, corrosive environments, or extreme mechanical stresses, Hyluo Inc. has the expertise to select the right material and machining process to deliver a solution that meets the highest standards of quality and performance.The aerospace industry, in particular, benefits from Hyluo Inc.'s CNC machined gears. Aerospace applications demand gears that can operate in the harshest of environments, from the extreme temperatures of space to the high speeds and forces encountered in aircraft propulsion systems. Hyluo Inc.'s gears are designed and manufactured to meet these rigorous performance requirements, providing aerospace companies with components they can rely on for the most demanding missions and operations.In the automotive industry, where efficiency, reliability, and performance are paramount, Hyluo Inc.'s CNC machined gears play a crucial role in ensuring the smooth and efficient operation of vehicle transmissions, engines, and other drivetrain systems. The company's commitment to delivering top-quality gears has earned them a reputation as a trusted partner for automotive manufacturers looking to enhance the performance and durability of their vehicles.Hyluo Inc.'s CNC machined gears have also found applications in the field of robotics, where precision and reliability are essential for the smooth functioning of robotic systems. By delivering gears that meet the highest standards of accuracy and performance, Hyluo Inc. has become a preferred supplier for robotics companies seeking to enhance the capabilities of their automation and robotics solutions.With a track record of delivering high-quality CNC machined gears and components to companies worldwide, Hyluo Inc. is well-positioned to continue making a significant impact in the manufacturing industry. Through their expertise in CNC machining and their commitment to meeting the unique needs of their customers, the company is poised to remain a key player in the supply chains of industry-leading manufacturers for years to come.

High-quality Aluminum Cylinder for Efficient Performance

Aluminum Cylinder Company Introduces New Innovative Product[Company Name] is proud to announce the release of its latest innovation in the field of aluminum cylinders. The company, a leading global manufacturer of high-quality aluminum products, has developed a new and improved type of aluminum cylinder that is set to revolutionize the industry.The new aluminum cylinder, designed and produced by [Company Name], provides superior performance and durability compared to traditional steel cylinders. Its advanced technology and unique design make it the perfect solution for a wide range of applications, including industrial, automotive, aerospace, and medical.Made from high-quality aluminum alloy, the new cylinder offers a significant reduction in weight compared to steel cylinders, making it more cost-effective and efficient. In addition, it is highly resistant to corrosion, ensuring a longer lifespan and lower maintenance costs."We are thrilled to introduce our new aluminum cylinder to the market," said [Spokesperson Name], CEO of [Company Name]. "This innovative product is the result of our commitment to research and development and our relentless pursuit of excellence in manufacturing. We are confident that it will meet and exceed the expectations of our customers across various industries."[Company Name] has a long-standing reputation for delivering top-notch aluminum products, and its new cylinder is no exception. The company's manufacturing process ensures the highest quality and precision, meeting or exceeding industry standards and regulations.In addition to its superior performance and durability, the new aluminum cylinder is also environmentally friendly. Aluminum is highly recyclable and sustainable, making it a preferred choice for companies aiming to reduce their carbon footprint and contribute to a greener future."We are proud to offer a product that not only delivers exceptional performance but also aligns with our commitment to environmental responsibility," added [Spokesperson Name]. "Our new aluminum cylinder embodies our dedication to innovation and sustainability, and we believe it will make a positive impact in the market."The new aluminum cylinder from [Company Name] is now available for purchase, and the company is already receiving inquiries and orders from customers worldwide. With its cutting-edge technology, exceptional quality, and environmental benefits, the product is expected to gain significant traction in the global market.[Company Name] remains committed to pushing the boundaries of aluminum manufacturing and delivering innovative solutions to its customers. The company's dedication to excellence and continuous improvement sets it apart as a leader in the industry, and its new aluminum cylinder is a testament to its unwavering commitment to innovation and customer satisfaction.As demand for lightweight, durable, and environmentally friendly products continues to grow across various industries, [Company Name] is poised to make a significant impact with its new aluminum cylinder. With its proven track record and advanced capabilities, the company is well-positioned to meet the evolving needs of its customers and drive positive change in the aluminum manufacturing sector.For more information about [Company Name] and its new aluminum cylinder, visit [company website] or contact [company email/phone number].In summary, [Company Name] has introduced an innovative, high-quality aluminum cylinder that offers superior performance, durability, and environmental benefits. The company's dedication to excellence and commitment to innovation make it a standout leader in the industry, and its new product is expected to make a lasting impact in the global market.

Custom Aluminum Prototype Machining Services: Fast and Accurate Results

Aluminum Prototype Machining: Shaping the Future of ManufacturingIn today's fast-paced and ever-evolving world of manufacturing, the demand for efficient and reliable aluminum prototype machining has never been greater. As industries continue to push the boundaries of innovation, the need for precision parts and components has become a pressing necessity. This is where the expertise and experience of {} come into play.With a reputation for delivering high-quality machining solutions, {} has been at the forefront of the industry for years. Specializing in aluminum prototype machining, the company has established itself as a trusted partner for numerous businesses across a wide range of sectors. From aerospace and automotive to medical and consumer electronics, their expertise has left an indelible mark on the industry.{} takes pride in its cutting-edge facilities and state-of-the-art equipment, which enable them to consistently meet the exacting demands of their clients. Utilizing advanced CNC machines and a team of highly skilled engineers, the company has the capability to handle complex projects with ease. Their commitment to precision and attention to detail ensures that every component they produce meets the highest standards of quality and accuracy.One of the key factors that set {} apart from its competitors is its unwavering dedication to innovation. The company is constantly investing in research and development to stay ahead of the curve and adapt to the ever-changing landscape of manufacturing. By leveraging the latest technologies and techniques, {} is able to offer cutting-edge solutions that cater to the unique needs of their clients.In addition to their technical proficiency, {} is also known for its exceptional customer service. The company takes a collaborative and consultative approach to every project, working closely with clients to understand their specific requirements and provide tailored solutions. This level of personalized attention has allowed {} to build strong, long-lasting relationships with its clients, earning their trust and loyalty.One of the most significant contributions of {} to the industry has been its commitment to sustainability. As the world becomes increasingly mindful of its environmental impact, the company has been proactive in implementing eco-friendly practices in its operations. From using recycled materials to minimizing waste and emissions, {} is dedicated to reducing its carbon footprint and promoting a greener, more sustainable future for manufacturing.Looking ahead, {} is poised to continue its leadership in the realm of aluminum prototype machining. With a relentless pursuit of excellence and a forward-thinking mindset, the company is well-equipped to meet the challenges of tomorrow's manufacturing landscape. By staying true to its core values of quality, innovation, and sustainability, {} is set to shape the future of manufacturing in more ways than one. Whether it's developing groundbreaking prototypes or producing intricate components, the company's impact on the industry is undeniable.With a strong foundation built on expertise, technology, and a customer-centric approach, {} embodies the best of what the manufacturing world has to offer. As industries continue to evolve and push the boundaries of innovation, the company's commitment to excellence ensures that it will remain a trusted and indispensable partner for businesses around the globe. Whether it's shaping the future of aerospace, automotive, medical, or any other sector, {} is set to lead the way in aluminum prototype machining for years to come.

Advanced Multi-Axis CNC Machining: Taking Precision to the Next Level

Multi Axis CNC Machining is a cutting-edge technology that has been revolutionizing the manufacturing industry in recent years. This advanced machining process involves using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to control the movements of multiple cutting tools on different axes simultaneously. This results in highly precise and efficient production of complex and intricate components.{Company Name} is a leading provider of Multi Axis CNC Machining services, with a proven track record of delivering high-quality and cost-effective solutions to a wide range of industries. With state-of-the-art facilities and a team of skilled engineers and technicians, {Company Name} is able to offer a comprehensive range of machining capabilities, including milling, turning, drilling, and grinding, all performed with the highest level of precision and accuracy.One of the key advantages of Multi Axis CNC Machining is its ability to produce parts with extremely tight tolerances and complex geometries that would be virtually impossible to achieve with conventional machining methods. This is particularly valuable in industries such as aerospace, automotive, medical, and defense, where the demand for intricately designed components is high. With Multi Axis CNC Machining, {Company Name} is able to meet the exacting requirements of its customers and deliver parts that are not only of the highest quality, but also produced in the most efficient manner possible.In addition to its precision and versatility, Multi Axis CNC Machining also offers significant time and cost savings compared to traditional machining methods. By utilizing advanced software and automation, {Company Name} is able to significantly reduce the time and labor required to produce complex parts, resulting in shorter lead times and lower production costs for its customers. This makes Multi Axis CNC Machining an excellent choice for businesses looking to streamline their manufacturing processes and improve their overall efficiency.Furthermore, {Company Name} is committed to staying at the forefront of technological advancements in the field of CNC machining. The company is constantly investing in the latest equipment and software to ensure that it remains at the cutting edge of the industry and is able to offer its customers the most advanced and innovative solutions available. By staying ahead of the curve, {Company Name} is able to provide its customers with the highest quality products and services, while also positioning itself as a leader in the rapidly evolving field of Multi Axis CNC Machining.As the demand for high-precision, complex components continues to grow across industries, the importance of Multi Axis CNC Machining as a manufacturing solution cannot be understated. With its unparalleled precision, efficiency, and cost-effectiveness, {Company Name} is well-equipped to meet the needs of its customers and help them stay ahead in today's competitive market. Whether it's producing intricate aerospace components, precision medical instrumentation, or complex automotive parts, {Company Name}'s Multi Axis CNC Machining capabilities are second to none, making it the go-to partner for businesses looking for top-of-the-line manufacturing solutions.