Precision CNC Swiss Machining: What You Need to Know

By:Admin

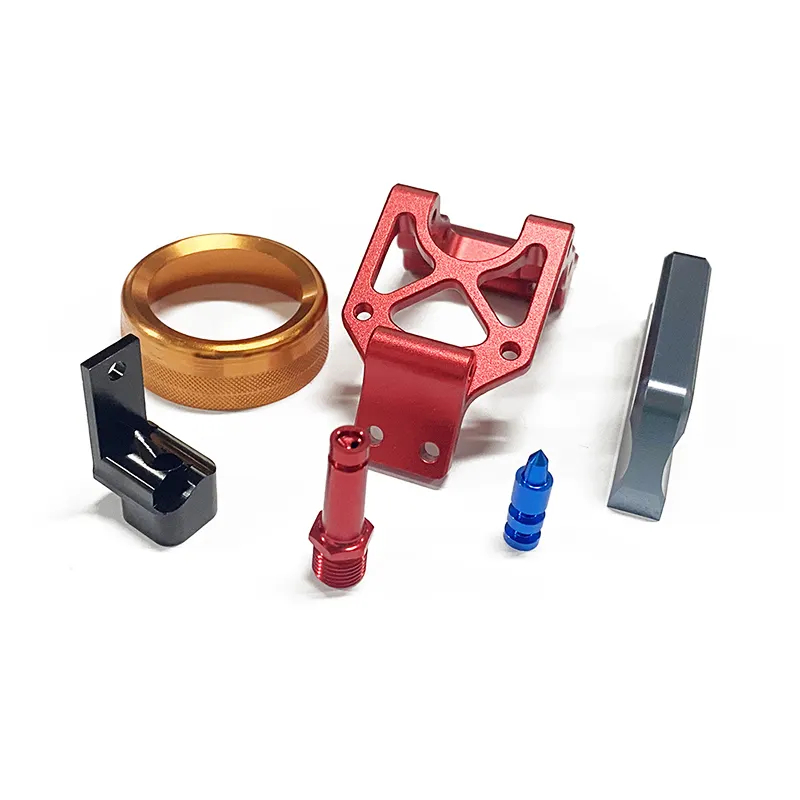

One of the key technologies that has contributed to Hyluo Inc.'s success in producing high-quality machined components is CNC Swiss machining. This advanced manufacturing process has allowed them to achieve tight tolerances and produce complex parts with a high degree of accuracy. CNC Swiss machining is particularly well-suited for small, intricate parts that require a high level of precision, making it an ideal choice for a wide range of industries.

CNC Swiss machining, also known as Swiss turning, is a type of precision machining that utilizes a sliding headstock and a guide bushing to support the material being machined. This allows for greater stability and accuracy, especially when working with small diameter parts. The machining process involves the use of multiple tools that can perform various operations such as turning, milling, drilling, and tapping, all in a single setup. This capability allows for faster production times and reduced setup costs, making CNC Swiss machining a cost-effective solution for producing high-quality components.

With their expertise in CNC Swiss machining, Hyluo Inc. has been able to meet the unique needs of their customers across a wide range of industries. From aerospace and automotive to medical and electronics, their precision machined components have found applications in various critical systems and devices. The ability to produce complex and intricate parts with tight tolerances has made them a trusted partner for companies seeking reliable and high-quality components.

In addition to their CNC Swiss machining capabilities, Hyluo Inc. also offers a range of value-added services to meet their customers' specific requirements. These services include design assistance, material selection, surface finishing, and quality inspection. By providing a comprehensive solution, they are able to support their customers throughout the entire manufacturing process, from initial concept to final production.

As part of their commitment to continuous improvement, Hyluo Inc. has invested in the latest CNC Swiss machining technology and equipment. This allows them to stay at the forefront of manufacturing innovation and deliver the highest quality machined components to their customers. Their state-of-the-art facility is equipped with advanced CNC Swiss lathes and inspection equipment, ensuring that every part meets the strictest quality standards.

Furthermore, Hyluo Inc. places a strong emphasis on quality management and process control. They have implemented rigorous quality assurance measures throughout their production processes, from incoming material inspection to final product verification. This commitment to quality has earned them various certifications and approvals, demonstrating their dedication to delivering excellence in every component they produce.

Looking ahead, Hyluo Inc. is poised to continue their growth and expand their capabilities in CNC Swiss machining. With a focus on customer satisfaction and innovation, they are well-positioned to meet the evolving needs of their customers and the industry. As they continue to invest in advanced technology and talent, they strive to remain a trusted partner for companies seeking precision machined components.

In conclusion, Hyluo Inc. has established itself as a leading provider of custom precision CNC machined components, with a strong focus on CNC Swiss machining. Their expertise, commitment to quality, and continuous improvement have made them a valuable partner for companies across various industries. With their advanced capabilities and dedication to excellence, Hyluo Inc. is well-equipped to meet the growing demand for high-quality machined components in the global market.

Company News & Blog

Professional Metal Machining Services for Precision Components and Parts

Metal Machining Services, a leading provider of custom precision CNC machined components, has announced a new partnership with Hyluo Inc. The partnership will further enhance Metal Machining Services' capabilities and expand their reach in providing high-quality machined parts to companies worldwide.Hyluo Inc. has been specializing in custom precision CNC machined components since 2010, with a strong track record of manufacturing precision machined components for companies across various industries. With over 10 years of experience, Hyluo Inc. has become an integral part of the supply chains of many industry-leading manufacturers. Their main products include CNC aluminum parts, CNC processing stainless steel parts, CNC copper parts, CNC titanium parts, CNC plastic parts, and more. This extensive range of offerings aligns perfectly with Metal Machining Services' commitment to delivering top-notch machined parts to its clients.The partnership between Metal Machining Services and Hyluo Inc. comes at a time when the demand for precision machined components is on the rise. With industries such as aerospace, automotive, medical, and electronics constantly seeking high-quality machined parts, both companies are well-positioned to cater to this growing demand."We are thrilled to announce our partnership with Hyluo Inc.," said a representative from Metal Machining Services. "Their expertise in CNC machining and their proven track record of delivering precision components make them an ideal partner for us. This collaboration will enable us to offer an even broader range of high-quality machined parts to our clients, further solidifying our position as a trusted provider in the industry."Through this partnership, Metal Machining Services will be able to tap into Hyluo Inc.'s extensive knowledge and experience in CNC machining. This will allow them to offer a wider variety of materials and components to their clients, as well as provide more specialized and intricate machining solutions.Furthermore, the collaboration will enable Metal Machining Services to streamline its operations and enhance its overall efficiency in delivering custom precision machined components. By leveraging Hyluo Inc.'s expertise and resources, Metal Machining Services will be able to optimize its manufacturing processes, reduce lead times, and offer competitive pricing to its customers."We are excited about the possibilities that this partnership brings," said a spokesperson from Hyluo Inc. "Metal Machining Services has a strong reputation for delivering top-quality machined parts, and we are confident that our collaboration will result in a seamless integration of our capabilities. Together, we will be able to provide our clients with a comprehensive range of precision machined components, all backed by our shared commitment to excellence."As Metal Machining Services and Hyluo Inc. join forces, both companies are poised to capitalize on the growing demand for precision machined components in various industries. With their combined expertise, resources, and dedication to delivering top-notch products, they are well-positioned to become a go-to source for custom CNC machined components for companies worldwide.In conclusion, the partnership between Metal Machining Services and Hyluo Inc. marks an exciting development in the world of precision machining. With their combined capabilities and commitment to excellence, both companies are set to solidify their position as leading providers of custom precision CNC machined components, offering a comprehensive range of high-quality machined parts to companies across the globe.

High-Quality 5-Axis CNC Machining Services Near Me

The demand for precision engineering and manufacturing services has been steadily increasing as industries continue to evolve and drive the need for advanced technology. With this demand comes the need for cutting-edge machining capabilities, and for many businesses, the search for "5 axis CNC machining near me" has become a top priority.One company that is meeting this demand head-on is {}. With their state-of-the-art facility and highly skilled team, they have become a go-to source for 5 axis CNC machining services. Their commitment to quality, precision, and customer satisfaction has made them a trusted partner for businesses across a wide range of industries.{} boasts a comprehensive range of machining capabilities, including 5 axis CNC machining. This advanced technology allows for the production of complex parts and components with unprecedented accuracy and efficiency. By utilizing 5 axis CNC machining, {} can offer their clients a level of precision and detail that is unmatched by traditional machining methods.The process of 5 axis CNC machining involves the use of computer-controlled tools and machinery to execute intricate cuts and movements on a workpiece. This allows for the creation of highly complex geometries and shapes, making it an ideal solution for industries such as aerospace, automotive, medical, and defense, among others. With their expertise in this area, {} has been able to provide their clients with the high-quality parts and components they need to drive their businesses forward.In addition to their advanced machining capabilities, {} offers a range of other services to support their clients' needs. This includes design and engineering support, material selection and sourcing, quality control and inspection, and finishing and coating options. By providing a comprehensive suite of services, {} is able to serve as a one-stop shop for all of their clients' manufacturing needs.One of the key factors that sets {} apart in the industry is their commitment to continuous improvement and innovation. They invest in the latest technology and equipment, and their team undergoes regular training to stay ahead of the curve in the rapidly evolving manufacturing landscape. This dedication to staying at the forefront of the industry ensures that {} is able to consistently deliver top-tier results for their clients.Another standout aspect of {} is their focus on customer collaboration and communication. They work closely with each client to understand their unique requirements and goals, and then tailor their approach to deliver the best possible results. This commitment to building strong, long-term relationships has earned them a reputation as a trusted and reliable manufacturing partner.As the demand for 5 axis CNC machining continues to grow, {} is well-positioned to meet the needs of a wide range of industries. Their advanced capabilities and unwavering commitment to quality make them a top choice for businesses in search of precision machining solutions. Whether it's producing complex aerospace components or intricate medical devices, clients can rely on {} to deliver exceptional results.In conclusion, the search for "5 axis CNC machining near me" leads to the doorsteps of {}. With their cutting-edge technology, skilled team, comprehensive services, and unwavering commitment to excellence, they have firmly established themselves as a leading provider of precision machining solutions. Whether clients are in need of 5 axis CNC machining or any other manufacturing services, they can trust {} to deliver the high-quality results they demand.

Precision Milling Machine Shop Near Me: Find Quality Services in Your Area

Today, we are excited to announce the grand opening of our new milling machine shop in the heart of [location]. Our state-of-the-art facility is equipped with the latest technology and staffed by highly skilled machinists, making us the go-to destination for all your milling machine needs.Our new shop is strategically located to serve the needs of businesses in the [location] area, providing a convenient and reliable source for high-quality milling machine services. Whether you are in the aerospace, automotive, or manufacturing industry, our shop is fully equipped to handle a wide range of projects, from prototyping to large-scale production.At our milling machine shop, we take great pride in our ability to deliver precision and quality in every project we undertake. With a focus on customer satisfaction, we are committed to meeting and exceeding your expectations, no matter how complex or challenging the job may be.In addition to our cutting-edge equipment, our team of machinists is highly experienced and dedicated to delivering superior results. We understand the importance of precision and accuracy in milling machine work, and we have the expertise to ensure that every project is completed to the highest standards.Furthermore, we are committed to staying ahead of the curve in the industry, regularly investing in new technology and training to ensure that we are always at the forefront of innovation. This dedication to continuous improvement means that our customers can always rely on us for the most advanced and efficient milling machine solutions.As part of our commitment to customer satisfaction, we also offer personalized service and attention to detail. We understand that every project is unique, and we take the time to listen to our customers' needs and tailor our solutions accordingly. Whether you have specific design requirements or tight deadlines to meet, we are dedicated to providing the personalized service and quality craftsmanship that you deserve.In addition to our milling machine services, we also offer a range of complementary solutions to meet your manufacturing needs. From CNC machining to metal fabrication, our shop is a one-stop destination for all your precision manufacturing requirements. We take pride in being a trusted partner to our customers, helping them achieve their goals with our comprehensive and reliable services.As we open our doors to the [location] community, we are excited to welcome new customers and build long-lasting relationships with businesses in the area. Our goal is to become the premier destination for milling machine services, delivering exceptional quality and value to every customer we serve.At our milling machine shop, we are not just a service provider; we are a partner in your success. With our unwavering commitment to excellence and customer satisfaction, you can trust us to be the reliable source for all your milling machine needs. We look forward to the opportunity to demonstrate our expertise and earn your trust as your preferred machining partner.In conclusion, our new milling machine shop in [location] is poised to set a new standard for excellence in the industry. With our cutting-edge technology, experienced team, and dedication to customer satisfaction, we are ready to meet the needs of businesses in the area and beyond. Whether you are in need of precision milling machine services or other manufacturing solutions, you can count on us to deliver exceptional quality and value. Thank you for choosing our shop to meet your machining needs, and we look forward to serving you with the highest level of professionalism and expertise.

Leading Precision Turning Company Provides Top-Quality Services for Manufacturing Needs

Precision Turning Inc, a leading manufacturer of custom precision CNC machined components has announced a strategic partnership with Hyluo Inc. The collaboration between the two companies is poised to revolutionize the industry and offer unparalleled precision and quality to their customers.Hyluo Inc. has been in the business of manufacturing precision machined components since 2010. With over a decade of experience, the company has established itself as a trusted partner for companies worldwide. They have been an integral part of the supply chains of many industry-leading manufacturers, providing a wide range of CNC machined components including aluminum parts, stainless steel parts, copper parts, titanium parts, plastic parts, and more.Precision Turning Inc, on the other hand, is known for its expertise in producing high-quality custom precision CNC machined components. With a focus on precision and accuracy, the company has built a reputation for delivering superior products to its customers. By joining forces with Hyluo Inc, Precision Turning Inc aims to further enhance its capabilities and expand its product offerings.The partnership between the two companies is expected to bring together their expertise and resources to provide customers with a comprehensive range of precision machined components. By leveraging their combined strengths, they aim to offer innovative solutions and unmatched quality to their customers across various industries.One of the key benefits of this collaboration is the ability to offer a wider range of materials and capabilities. Hyluo Inc's extensive experience in working with different materials such as aluminum, stainless steel, copper, titanium, and plastic, combined with Precision Turning Inc's precision machining capabilities, will enable them to cater to diverse customer requirements.Additionally, the partnership will also enable both companies to streamline their operations and optimize their manufacturing processes. By leveraging each other's expertise and resources, they aim to enhance efficiency and reduce lead times, ensuring faster delivery of high-quality precision machined components to their customers.Furthermore, the collaboration between Precision Turning Inc and Hyluo Inc is expected to open up new opportunities for both companies in terms of market expansion and customer acquisition. By combining their strengths, they aim to reach new customers and expand their presence in the global market, solidifying their position as industry leaders.The partnership is also expected to drive innovation and continuous improvement in the production of precision machined components. By sharing knowledge, best practices, and technology, the companies aim to stay ahead of the curve and meet the evolving needs of their customers in an increasingly competitive market."We are thrilled to announce our partnership with Hyluo Inc," said a spokesperson for Precision Turning Inc. "By joining forces, we aim to offer our customers a wider range of precision machined components and unparalleled quality. We are confident that this collaboration will bring significant benefits to both companies and further strengthen our position in the industry."Overall, the partnership between Precision Turning Inc and Hyluo Inc marks an important milestone in the industry. By combining their expertise, resources, and capabilities, the two companies aim to raise the bar for precision machined components and provide customers with exceptional products and services. As they move forward with this partnership, they are poised to set new standards and drive innovation in the industry, ultimately benefiting their customers and the market as a whole.

How to Implement Axis Turning in Your Manufacturing Process

The renowned company, Axis Turning, has been making waves in the industry with its precision machining and manufacturing services. With a commitment to quality, innovation, and customer satisfaction, Axis Turning has earned a reputation as a leader in the field. The company's expertise lies in CNC turning, milling, and Swiss machining, and they are renowned for their ability to produce complex and high-tolerance components for a wide range of industries.Recently, Axis Turning has made headlines with their latest technological advancements and expansions to meet the growing demand for their services. By investing in state-of-the-art equipment and employing a team of highly skilled engineers and technicians, the company has positioned itself as a go-to solution for businesses looking for reliable and efficient manufacturing processes.The company's commitment to excellence is evident in their approach to each project. They work closely with their clients to understand their specific needs and requirements, and then leverage their expertise and technology to deliver precision components that meet or exceed expectations. From prototyping to full-scale production runs, Axis Turning has the capabilities and resources to handle projects of any size and complexity.One of the key factors that sets Axis Turning apart from its competitors is their ability to provide quick turnaround times without compromising on quality. This is made possible through their streamlined processes and efficient production methods. By optimizing every stage of the manufacturing process, they are able to deliver parts and components in a timely manner, helping their clients meet their own project deadlines.In addition to their commitment to quality and efficiency, Axis Turning is also dedicated to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, including recycling and waste reduction initiatives. This commitment to sustainability not only aligns with their corporate values, but also resonates with clients who are looking to partner with environmentally conscious suppliers.As Axis Turning continues to expand its presence in the industry, they are also focusing on building strong relationships with their clients. With a customer-centric approach, the company aims to provide a seamless and transparent experience, from the initial consultation to the final delivery. This includes open communication, collaborative problem-solving, and a commitment to delivering value beyond the finished product.Looking ahead, Axis Turning is poised for further growth and success. With a solid foundation built on expertise, technology, and customer satisfaction, the company is well-positioned to continue leading the way in precision machining and manufacturing. Their dedication to quality, innovation, and sustainability will undoubtedly set them apart in the industry, and we can expect to see even more impressive achievements from Axis Turning in the future. With their unwavering commitment to excellence, the company is set to remain at the forefront of the industry for years to come.

High-Quality CNC Turning Machine Parts for Precision Manufacturing

Hyluo Inc. specializes in custom precision CNC machined components and has been a prominent player in the industry for over a decade. With a wide range of products that include CNC aluminum, stainless steel, copper, titanium, and plastic parts, the company has established itself as an integral part of the supply chains of numerous industry-leading manufacturers worldwide.One of the main services provided by Hyluo Inc. is the manufacturing of CNC turning machine parts. Utilizing advanced technology and a team of skilled machinists, the company is able to produce high-quality components that meet the exact specifications of their clients. This has made them a trusted partner for companies operating in various sectors, including automotive, aerospace, medical, and consumer electronics.The CNC turning process involves the use of computer-controlled lathes to create precise and intricate designs. It allows for the production of complex shapes and features with a high degree of accuracy and repeatability. This makes it a crucial part of the manufacturing process for many industries, where precision and consistency are of utmost importance.Hyluo Inc. has invested in state-of-the-art CNC turning machines to ensure that they are able to meet the demands of their clients. The company's commitment to quality and innovation has allowed them to stay at the forefront of the industry, consistently delivering components that exceed customer expectations.In addition to their technical capabilities, Hyluo Inc. takes pride in their ability to work closely with their clients to understand their specific needs and requirements. This proactive approach has allowed them to build long-lasting relationships with their customers, who value the company's dedication to meeting deadlines and delivering exceptional results.The company's CNC turning machine parts are used in a wide range of applications. From small, intricate components for medical devices to larger, more robust parts for automotive and aerospace applications, Hyluo Inc. has the expertise and capabilities to fulfill the diverse needs of their clients.Furthermore, the company's commitment to sustainability and environmental responsibility sets them apart in the industry. Hyluo Inc. recognizes the importance of minimizing their environmental impact, and they have implemented various measures to reduce waste and energy consumption in their production processes. This has made them an attractive partner for companies looking to align themselves with environmentally conscious suppliers.As a testament to their commitment to excellence, Hyluo Inc. has earned various certifications and recognitions for their quality management systems. These accolades reinforce the company's position as a reliable and trustworthy supplier of CNC machined components.Looking ahead, Hyluo Inc. is focused on further expanding their capabilities and capacity to meet the growing demands of their customers. With an eye towards emerging technologies and industry trends, the company is well-positioned to continue as a leader in the CNC machining industry.In conclusion, Hyluo Inc. has established itself as a respected provider of custom precision CNC machined components, including CNC turning machine parts. With a strong focus on quality, innovation, and customer satisfaction, the company has become an integral part of the supply chains of industry-leading manufacturers worldwide. As they continue to grow and evolve, Hyluo Inc. is poised to further solidify their position at the forefront of the CNC machining industry.

High-Quality Precision CNC Turned Parts for Industrial Use

Hyluo Inc. has been making waves in the manufacturing industry with its specialized expertise in custom precision CNC machined components. The company, founded in 2010, has quickly risen to prominence by delivering high-quality products to companies worldwide. With over 10 years of experience, Hyluo Inc. has become an integral part of the supply chains of many industry-leading manufacturers.Hyluo Inc.'s main products include CNC aluminum parts, CNC processed stainless steel parts, CNC copper parts, CNC titanium parts, and CNC plastic parts. The company's extensive range of capabilities allows them to serve a wide variety of industries, from aerospace and automotive to medical and electronics.One of Hyluo Inc.'s key strengths lies in their precision CNC turned parts. These components are produced with the highest level of accuracy and consistency, meeting the exact specifications of their clients. By leveraging cutting-edge technology and advanced manufacturing processes, the company is able to deliver complex and intricate parts with tight tolerances.The CNC aluminum parts manufactured by Hyluo Inc. are known for their lightweight yet durable properties. These parts are widely used in the aerospace and automotive industries, where high strength-to-weight ratio is crucial. Hyluo Inc.'s expertise in aluminum machining allows them to produce components that meet the stringent quality standards of these demanding sectors.When it comes to CNC processing stainless steel parts, Hyluo Inc. has established a reputation for excellence. Stainless steel is a versatile material known for its corrosion resistance and high strength. The company's precision machining capabilities enable them to create stainless steel parts that are both aesthetically pleasing and functional, making them ideal for various applications in the medical, food processing, and architectural industries, among others.In addition to aluminum and stainless steel, Hyluo Inc. also specializes in CNC copper parts. Copper is a highly conductive material that finds extensive use in electrical and electronic applications. Hyluo Inc.'s precision machining expertise allows them to produce intricate copper components with the utmost precision, ensuring optimal performance in their intended applications.Furthermore, the company's CNC titanium parts are a testament to their capabilities in machining challenging materials. Titanium is renowned for its high strength-to-weight ratio, making it an essential material in aerospace, medical, and marine industries. Hyluo Inc.'s proficiency in CNC machining titanium allows them to meet the stringent requirements of these industries, producing components that are not only lightweight but also incredibly durable.Last but not least, Hyluo Inc. is capable of producing CNC plastic parts to cater to industries where lightweight and corrosion-resistant materials are required. The versatility of plastics allows for a wide range of applications, from consumer electronics and automotive components to medical devices and industrial equipment. Hyluo Inc.'s precision CNC machining of plastic parts ensures that they meet the exact specifications and performance requirements of their clients.In conclusion, Hyluo Inc. has solidified its position as a leading manufacturer of custom precision CNC machined components. With a track record of delivering high-quality products to companies worldwide, the company has demonstrated its commitment to excellence in precision machining. Whether it's aluminum, stainless steel, copper, titanium, or plastic, Hyluo Inc. has the expertise and capabilities to meet the diverse needs of industries across the globe. As they continue to expand their capabilities and serve new markets, Hyluo Inc. is well-positioned to remain a key player in the manufacturing industry for years to come.

Guide to 5-Axis Milling and Its Benefits

C Axis Milling has recently been introduced by a cutting-edge manufacturing company, which has revolutionized the way industrial parts and components are produced. This state-of-the-art technology has significantly enhanced the company's capabilities and has reinforced its position as an industry leader in precision engineering.The introduction of C Axis Milling has been a game changer for the company, allowing for the production of complex components with unparalleled precision and efficiency. This technology has enabled the company to meet the increasing demands of its clients for high-quality, intricate parts, while also significantly reducing production times. As a result, the company has been able to take on a wider range of projects and deliver exceptional results to its clients in a more timely manner.C Axis Milling utilizes advanced multi-axis machining capabilities to produce highly intricate and detailed components. This technology allows for the simultaneous movement of the cutting tool along multiple axes, resulting in the production of complex shapes and features that were previously unattainable with traditional machining methods. This level of precision has allowed the company to expand its offerings to clients in industries such as aerospace, automotive, medical, and electronics, among others.One of the key advantages of C Axis Milling is its ability to streamline the manufacturing process. By integrating this technology into its production line, the company has been able to reduce the number of operations required to produce a component, leading to faster turnaround times and ultimately lower costs for its clients. Additionally, the high level of precision achieved with C Axis Milling has greatly improved the overall quality of the components, ensuring that they meet the strictest industry standards.Furthermore, the company's investment in C Axis Milling demonstrates its commitment to staying at the forefront of technological advancements in the manufacturing industry. By continuously investing in the latest and most advanced equipment, the company is able to offer its clients cutting-edge solutions that meet the evolving needs of modern industry. This commitment to innovation has solidified the company's reputation as a trusted partner for businesses seeking reliable, high-quality manufacturing services.In addition to its technological capabilities, the company's team of highly skilled engineers and technicians play a crucial role in the successful implementation of C Axis Milling. Their expertise and experience have been instrumental in maximizing the potential of this advanced technology, ensuring that each component produced meets the exact specifications of the client. Through their dedication and attention to detail, the company has been able to consistently deliver exceptional results to its clients, establishing long-term partnerships based on trust and mutual success.As the company continues to push the boundaries of what is possible in precision engineering, the introduction of C Axis Milling represents a significant milestone in its journey towards excellence. By embracing this cutting-edge technology, the company has positioned itself as a leader in the manufacturing industry, capable of taking on the most challenging and intricate projects with confidence and precision.In conclusion, C Axis Milling has propelled the company to new heights in the world of precision engineering. This innovative technology has redefined the way industrial components are produced, allowing for the creation of highly intricate and complex parts with unmatched precision and efficiency. With its investment in C Axis Milling, the company has reaffirmed its commitment to providing its clients with the highest quality manufacturing solutions, solidifying its position as a trusted partner in the industry.

High-Quality Machining Factory: Delivering Superior Products for Your Business Needs

Machining Factory, a leading provider of custom precision CNC machined components, has been making waves in the manufacturing industry since its establishment in 2010. With a strong focus on quality and precision, the company has become an integral part of the supply chains of industry-leading manufacturers worldwide.Specializing in a wide range of materials, including aluminum, stainless steel, copper, titanium, and plastic, Machining Factory has built a reputation for delivering high-quality, custom machined components to meet the unique needs of its diverse clientele.Over the past decade, Machining Factory has consistently demonstrated its commitment to excellence, earning the trust and loyalty of customers in a variety of industries, including aerospace, automotive, electronics, and medical equipment manufacturing. The company's dedication to precision and accuracy has made it a go-to partner for companies seeking reliable, high-quality machined components.One of the key factors driving Machining Factory's success is its state-of-the-art CNC machining capabilities. The company's advanced machinery and cutting-edge technology enable it to produce components with tight tolerances and complex geometries, meeting the most demanding specifications and requirements. This level of precision has set Machining Factory apart from its competitors, establishing it as a leader in the custom CNC machining industry.Furthermore, Machining Factory's team of highly skilled engineers and machinists brings a wealth of expertise and experience to every project, ensuring that each component is manufactured to the highest standards. The company's commitment to continuous improvement and innovation further enhances its ability to deliver exceptional results, keeping it at the forefront of the industry.In addition to its focus on quality and precision, Machining Factory places a strong emphasis on customer satisfaction. The company works closely with each client to understand their unique needs and objectives, providing personalized service and support throughout the manufacturing process. This customer-centric approach has earned Machining Factory a reputation for reliability, responsiveness, and flexibility, further solidifying its position as a preferred partner for custom CNC machined components.Looking ahead, Machining Factory is poised for continued growth and success, driven by its unwavering commitment to excellence and its ability to adapt to the evolving needs of the manufacturing industry. As the demand for high-quality, custom machined components continues to rise, the company is well-positioned to meet the challenges and opportunities that lie ahead.With a proven track record of delivering superior results and exceeding customer expectations, Machining Factory remains a trusted and valued partner for companies seeking precision CNC machined components. As it continues to push the boundaries of innovation and excellence, the company is set to further solidify its position as a leader in the global manufacturing landscape.In summary, Machining Factory has established itself as a premier provider of custom precision CNC machined components, delivering exceptional quality, precision, and customer satisfaction. With a steadfast commitment to excellence and a focus on continuous improvement, the company is well-equipped to meet the needs of industry-leading manufacturers worldwide, making it an indispensable partner in today's competitive manufacturing environment.

Advanced Multi-Axis CNC Machining: Taking Precision to the Next Level

Multi Axis CNC Machining is a cutting-edge technology that has been revolutionizing the manufacturing industry in recent years. This advanced machining process involves using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to control the movements of multiple cutting tools on different axes simultaneously. This results in highly precise and efficient production of complex and intricate components.{Company Name} is a leading provider of Multi Axis CNC Machining services, with a proven track record of delivering high-quality and cost-effective solutions to a wide range of industries. With state-of-the-art facilities and a team of skilled engineers and technicians, {Company Name} is able to offer a comprehensive range of machining capabilities, including milling, turning, drilling, and grinding, all performed with the highest level of precision and accuracy.One of the key advantages of Multi Axis CNC Machining is its ability to produce parts with extremely tight tolerances and complex geometries that would be virtually impossible to achieve with conventional machining methods. This is particularly valuable in industries such as aerospace, automotive, medical, and defense, where the demand for intricately designed components is high. With Multi Axis CNC Machining, {Company Name} is able to meet the exacting requirements of its customers and deliver parts that are not only of the highest quality, but also produced in the most efficient manner possible.In addition to its precision and versatility, Multi Axis CNC Machining also offers significant time and cost savings compared to traditional machining methods. By utilizing advanced software and automation, {Company Name} is able to significantly reduce the time and labor required to produce complex parts, resulting in shorter lead times and lower production costs for its customers. This makes Multi Axis CNC Machining an excellent choice for businesses looking to streamline their manufacturing processes and improve their overall efficiency.Furthermore, {Company Name} is committed to staying at the forefront of technological advancements in the field of CNC machining. The company is constantly investing in the latest equipment and software to ensure that it remains at the cutting edge of the industry and is able to offer its customers the most advanced and innovative solutions available. By staying ahead of the curve, {Company Name} is able to provide its customers with the highest quality products and services, while also positioning itself as a leader in the rapidly evolving field of Multi Axis CNC Machining.As the demand for high-precision, complex components continues to grow across industries, the importance of Multi Axis CNC Machining as a manufacturing solution cannot be understated. With its unparalleled precision, efficiency, and cost-effectiveness, {Company Name} is well-equipped to meet the needs of its customers and help them stay ahead in today's competitive market. Whether it's producing intricate aerospace components, precision medical instrumentation, or complex automotive parts, {Company Name}'s Multi Axis CNC Machining capabilities are second to none, making it the go-to partner for businesses looking for top-of-the-line manufacturing solutions.